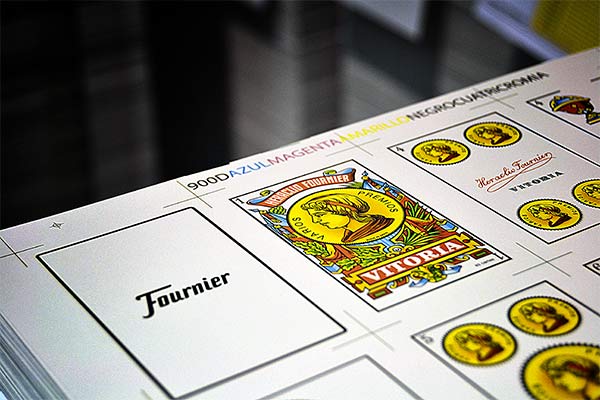

Since 1870, the year in which a small, rudimentary workshop was set up in Vitoria, to the present day, when the company now occupies a sophisticated modern industrial plant with the latest technology, Naipes Fournier has remained the home of a pioneering company. Fournier has been adapting to the technological advances that have taken place since its founding and development. A centenary history based on tradition, but also constant innovation and the desire to continuously improve the quality of its playing cards, considered by many to be the best in the world.

Fournier Quality is based on an exclusive selection of raw materials and a manufacturing process equipped with strict quality controls that result in a unique product with the following characteristics:

There are two types of finish, both for plastic and card stock. To this effect, we have exclusive service contracts with suppliers that manufacture these materials only for us, following strict material quality specifications. The outstanding quality of the components used in the manufacture of Fournier playing cards means that the most demanding players on the five continents consider us unique in the world. The manufacturing control process guarantees a high standard of quality, higher even than the market standard due to a distinctive manufacturing technique that differs from that used by the rest of competitors.

The types of finish are:

Special soft fibre card stock, varnished on both sides with a layer of opaque black glue or card stock with a linen finish varnished on both sides with a layer of opaque glue.

High quality PVC with specific treatment for casinos.

Our products undergo exhaustive quality controls, from raw material to the finished product. All the quality checks applied to the products analyse the following characteristics of the deck.

Each playing card is subjected to 12 quality checks during the manufacturing process, including an Intelligent Eye check at the end of the process and an optical infrared light test to make sure that each deck contains 55 cards.

Each card is printed with a code that allows us to control the traceability of all production, controlling the passage of each product in the production process from the raw materials to the point of sale.

If you wish to receive the latest news from Fournier in your email

Sign up!

Are you a distributor, collector, card fan, professional player? At Fournier we have the best exclusive information from within the sector, personalized to suit your interests.

Sign up!